DOC-Diesel oxidation catalyst

FOB Price:

Get Latest Price

Min.Order Quantity:

10 Piece/Pieces

Supply Ability:

100,000 Piece/Pieces per Month

Port:

SHENZHENG

Payment Terms:

L/C,T/T

- Description

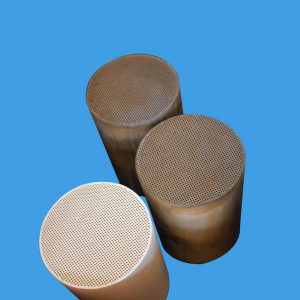

DOC (Diesel oxidation catalyst)

Background:

With increasing appearance of diesel engine automobile, the particulate from emission, mainly carbon, enhances the pollution to the environment. The US environmental office promulgated the particulate regulation for diesel engine, stipulating the particulate in diesel passenger car’s emission should meet the criterion: below 2.0g/mile. The diesel particulate filter is able to filter above 80% carbon smoke particulate, which would be a great help to solve the problem of air pollution in city.

Problem Analysis:

- What is DOC?

DOC catalyst is a oxidation catalyst part, which can efficiently purify the diesel engine emission (reduce the emission of CO and HC), and carry on an efficient oxidation reaction to soluble organic matter (SOF) from the diesel exhaust particles, particulate purifying rate can reach 50%~90%, the DOC products are widely used in buses, trucks, construction machinery and diesel engine emission control.

Diesel oxidation catalyst (DOC) is based on cordierite honeycomb ceramics as a support coated with an oxidation catalyst that converts CO, HC and soot particles into harmless CO2 and H2O. When the catalyst is coated on the carrier, it becomes a selective catalyst (SCR) Under the action of the catalyst, ammonia is discharged into the exhaust gas and NOx is reduced to N2 and H2O to achieve the purpose of processing unfixed nitrogen oxides. The device is suitable for all of our European Union phase four and you must comply with strict emission standards whether you are on the road or shutting down a diesel engine. DOC is part of the technology we provide to help you meet Phase IV and Level 4 mid-term or final emission standards. It breaks down pollutants in the exhaust gas from diesel engines and helps to reduce particulate matter (PM), which is similar to catalytic converters in automobiles.

- How it works?

If the DPF is coated with noble metal, black smoke with carbon particulate from diesel engine, pass through a special tube and enter the filter. The carbon smoke particulate is absorbed to the filter made of metallic fiber .when particulate absorption reaches some degree, the tail burner would be ignited to burning automatically. In this case, the particulate absorbed is burned out and turned into nontoxic CO2, then discharge. The full device is designed as double room structure, and filtration and recycle are going in different areas, making them non-disturbed. The system can work automatically whatever working condition .The special filter made by honeycomb ceramic, ceramic particulate filter, acts as capturing device, can capture the carbon particle which diameter is less than 30 micron.

Product Applications:

The DOC products are widely used in buses, trucks, construction machinery and diesel engine emission control.

Purification Effect:

1) Removal of particulate matter (black smoke) emitted from diesel vehicles into toxic, noxious and offensive gases such as CO, HC, NOX and be convert into harmless carbon dioxide and water discharge with certain silencing function.

2) Removal of particulate matter (PM), gas (CO), oil odor (HC), NOX removal efficiency parameters of exhaust gas are:

- Particle removal efficiency reached 85-98%

- CO removal efficiency reached 75-90%

- NOXremoval efficiency reached 10-40%

Product advantages:

1) Good handling performance of HC and CO

2) Small pressure loss, good particle trapping performance.

3) Good thermal shock resistance, good adsorption performance, low thermal expansion technology and a certain degree of mechanical strength

4) Good compatibility with various catalyst active components, which is widely used as an ideal carrier for catalytic purification of automobile exhaust gas.

-浅色-180x180.jpg)

-浅色-300x300.jpg)